Lately, more and more homeowners are turning to Thermal Fiber Insulation when it comes to keeping their homes energy-efficient and sustainable. Have you seen the latest numbers? According to the 2023 Global Insulation Market Report, the industry’s expected to hit around $80 billion by 2025 — all thanks to folks seeking smarter, eco-friendly building solutions. That kind of growth really shows how important it is to pick the right insulation and get it installed properly in your home.

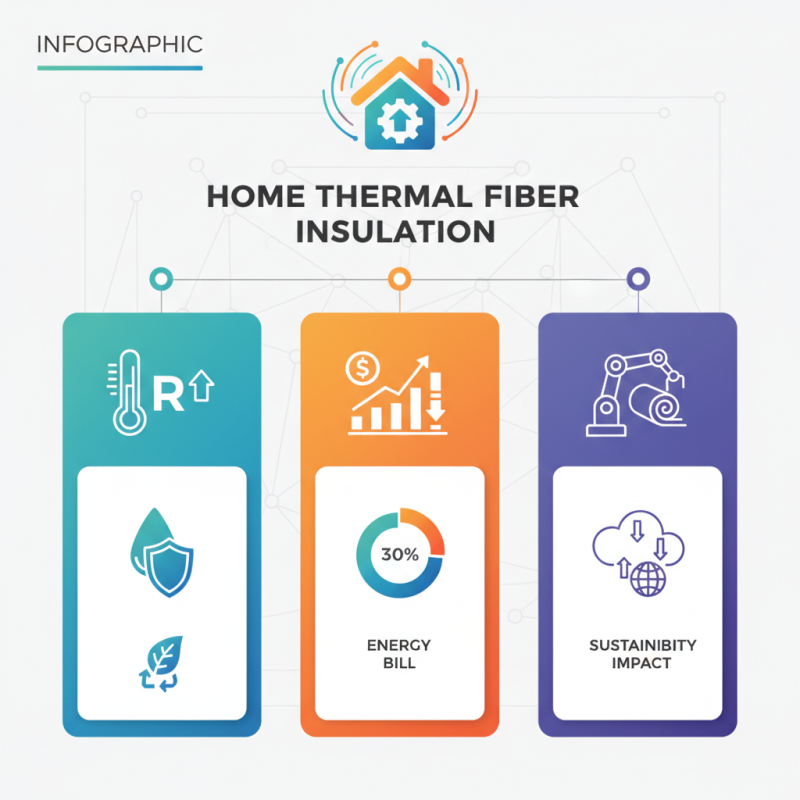

I recently heard Dr. Emily Roberts, a well-known expert in Thermal Insulation, talk about how much difference good insulation can make. She mentioned that, if you choose the right type, homeowners could save up to 30% on their energy bills every year. That’s pretty impressive, right? Her advice also highlights some key things to consider — like the R-value, moisture resistance, and how eco-friendly the materials are. Knowing these details can help folks not only cut down their carbon footprint but also make their homes comfier and more efficient.

As we edge towards 2025, new tech in Thermal Fiber Insulation is becoming more and more part of the conversation. With sustainability at the forefront, there are more options than ever for homeowners. It’s really an exciting time, but it also means you’ve gotta stay informed and make smart choices as you navigate this evolving landscape.

Choosing the Right Type of Thermal Fiber Insulation for Your Home

When selecting thermal fiber insulation for your home, it is essential to consider various factors to ensure maximum efficiency and comfort. One of the first steps is to understand the different types of insulation available, including fiberglass, mineral wool, and cellulose. Each material has unique properties, such as thermal resistance, sound absorption, and moisture resistance. For instance, fiberglass is lightweight and resistant to moisture, making it a popular choice for attics and wall cavities, while mineral wool offers excellent fire resistance and soundproofing benefits, which can be advantageous in residential construction.

Another critical aspect to consider is the insulation's R-value, which measures its thermal resistance. A higher R-value indicates better insulating capabilities, which translates into lower energy bills and a more comfortable living environment. Additionally, it's essential to evaluate the areas of your home that require insulation, such as exterior walls, attics, basements, and crawl spaces, as different areas may benefit from different types of thermal insulation. Proper installation is also crucial, as gaps or compression can significantly reduce effectiveness. By assessing these factors, homeowners can choose the right type of thermal fiber insulation that meets their specific needs and ensures a well-insulated home.

Evaluating the R-Value and Thermal Performance of Insulation Materials

When selecting thermal fiber insulation for your home, understanding the R-value is critical. The R-value measures the Insulation Material's resistance to heat flow; the higher the R-value, the better the insulation's effectiveness. According to the U.S. Department of Energy, optimal R-values vary by climate zone, ranging from R-30 to R-60 for attics and R-13 to R-21 for walls in typically colder regions. This performance metric not only influences energy efficiency but also helps in assessing potential energy savings over time. A study by the National Renewable Energy Laboratory indicates that upgrading to higher R-value insulation can lead to a significant reduction in heating and cooling costs, often realizing savings that amount to hundreds of dollars annually.

In addition to R-value, thermal performance also considers other factors such as air permeability and moisture resistance. For instance, fiberglass and cellulose insulation provide different thermal properties alongside their R-values. Fiberglass tends to have a higher R-value per inch, but cellulose offers superior air sealing capabilities due to its density, which can result in lower energy loss. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) recommends evaluating both the thermal resistance and overall performance of insulation materials in real-world applications. Applying a holistic approach ensures that home insulation not only meets R-value benchmarks but also effectively mitigates energy transfer through a building envelope, enhancing overall energy efficiency for homeowners.

Understanding Different Installation Methods for Fiber Insulation

When it comes to installing thermal fiber insulation in your home, understanding the different installation methods is crucial to achieving optimal energy efficiency and comfort. One of the most common installation techniques is the batts method, where pre-cut fiber insulation is fitted between wall studs, floor joists, and ceiling rafters. This method is relatively straightforward for DIY enthusiasts, as it requires minimal tools. However, ensuring a snug fit is essential to prevent air gaps, which can compromise insulation performance.

Another effective approach is the blown-in insulation method. This involves using a machine to blow loose fiber insulation into the desired spaces, making it ideal for irregularly shaped areas or retrofitting insulation in existing structures. Blown-in insulation can fill voids and odd corners, providing superior coverage compared to batts. It’s important to note that this method may require professional assistance for proper installation, especially if you want to achieve the recommended depth and density for maximum thermal performance.

Lastly, the spray foam insulation technique offers a versatile and highly effective alternative. It involves applying a liquid foam that expands to fill all gaps and cracks, creating an airtight seal. This method is particularly useful for areas with high moisture levels or where pest control is a concern. However, it can be more expensive than traditional fiber insulation methods and typically requires professional expertise to apply correctly. Each of these installation methods has its own advantages and considerations, making it essential to evaluate your specific needs before proceeding.

Preparing Your Home for Installation: Tools and Safety Measures

Preparing your home for the installation of thermal fiber insulation requires careful planning and consideration of essential tools and safety measures. According to the U.S. Department of Energy, proper insulation can reduce heating and cooling costs by up to 20%, making it critical to approach the installation process with diligence. Before beginning, homeowners should gather necessary tools, such as a utility knife, straightedge, measuring tape, and safety goggles.

Additionally, it is advisable to have a dust mask and gloves on hand to protect against airborne fibers that may be released during the installation process.

Safety is paramount when dealing with insulation materials. The Occupational Safety and Health Administration (OSHA) emphasizes the importance of following safety protocols to minimize risks. This includes ensuring proper ventilation in the work area to avoid inhaling dust. Homeowners should also be aware of their surroundings, using ladders safely and ensuring that the workspace is free from hazards. Ensuring that all family members and pets are kept away from the installation area can help prevent accidents.

By prioritizing these tools and safety measures, you can create a successful and efficient installation process while enhancing the energy efficiency of your home.

Step-by-Step Guide to Installing Thermal Fiber Insulation

When it comes to enhancing the energy efficiency of your home, installing thermal fiber insulation is a vital step. This eco-friendly choice not only helps maintain comfortable indoor temperatures but also significantly reduces energy bills. According to the U.S. Department of Energy, properly insulated homes can save homeowners up to 15% on heating and cooling costs, highlighting the importance of a well-executed installation.

To begin the installation process, first measure the areas where insulation will be added, ensuring you account for any gaps or irregularities in the structure. Choose the right thickness of thermal fiber insulation based on the recommended R-value for your climate zone. This information can typically be found in local building codes. During installation, make sure to wear protective gear, including gloves and masks, to avoid irritation from the insulation material.

**Tips:** Always start from the top down when insulating ceilings or walls to prevent thermal bridging. Additionally, check for moisture barriers; these are crucial in preventing mold growth behind the insulation. Be sure to seal any air leaks around windows and doors prior to installation to maximize the insulation’s effectiveness.

Common Mistakes to Avoid During Insulation Installation

When installing thermal fiber insulation in your home, it's crucial to be aware of common mistakes that can undermine the effectiveness of your insulation. One frequent error is inadequate preparation of the installation area. Before starting, ensure that the space is clean and free from dust, debris, and existing mold, as these can compromise the insulation's performance. Additionally, proper sealing of gaps and cracks is essential; neglecting this step can lead to air leaks and significantly reduce the insulation's ability to regulate temperature effectively.

Another mistake to avoid is improper installation techniques. Many homeowners may rush through the process or fail to follow manufacturer guidelines, which can result in insufficient coverage or compressing the insulation material. This compression diminishes its R-value, ultimately decreasing thermal efficiency. It's also important to pay attention to the orientation of the insulation. Installing it incorrectly can lead to moisture buildup and subsequent damage. Taking the time to perform a thorough installation, while avoiding these pitfalls, will ensure that your home benefits from effective thermal fiber insulation for years to come.

2025 Thermal Fiber Insulation Efficiency Comparison

Maintaining and Upgrading Your Insulation for Maximum Efficiency

Maintaining and upgrading your thermal fiber insulation is crucial for ensuring optimal energy efficiency in your home. Over time, insulation can become less effective due to factors such as settling, moisture, and degradation. Regularly inspecting your insulation will help identify any issues early on, ensuring that your home remains comfortable and your energy bills stay low. Look for signs of wear, such as gaps or dampness, which can indicate that replacement or additional insulation may be necessary.

When considering upgrades, focus on materials that enhance thermal performance while being environmentally friendly. Options like recycled fibers can provide superior insulation properties without compromising sustainability. Additionally, if you are expanding or renovating your living spaces, ensure that any new insulation installed matches or exceeds the performance of the existing material. Implementing proper installation techniques and sealing any air leaks will further boost efficiency, leading to a more sustainable and cost-effective home environment.

Enhancing Efficiency and Safety: The Benefits of Removable Valve Insulation Covers in Industrial Applications

In industrial settings, the need for effective insulation is paramount to both safety and efficiency. Removable valve insulation covers serve as an essential component in this regard, providing a myriad of benefits that enhance operational performance. These covers maintain optimal temperature control, significantly reducing heat loss and energy consumption, while also protecting personnel from hazardous temperatures. Designed to withstand a broad temperature range from -70°C to 1000°C, they are well-suited for various industrial applications.

Constructed with a thermal conductivity of less than 0.035 w/(m.k) at normal temperature, these insulation covers are not only efficient but also durable, boasting a material density between 100-200 kg/m3 and a thickness of 35mm-50mm. Their flame retardant properties ensure a high level of safety, rendering them non-flammable and able to resist potential fire hazards. Moreover, the covers' anti-corrosion characteristics, including resistance to acids, alkalis, water, and oils, extend their operational lifespan to over ten years, making them a reliable choice for demanding environments. By utilizing removable valve insulation covers, industries can achieve enhanced efficiency and safety, protecting both their processes and workforce.

FAQS

: Selecting the right type of thermal fiber insulation is essential for maximizing efficiency and comfort in the home. Different insulation materials have unique properties that can affect thermal resistance, sound absorption, and moisture resistance.

The common types of thermal fiber insulation include fiberglass, mineral wool, and cellulose. Each material offers distinct advantages, such as moisture resistance in fiberglass and excellent fire resistance in mineral wool.

R-value measures the thermal resistance of insulation materials, with a higher R-value indicating better insulating capabilities that can lead to lower energy bills and enhanced comfort.

Areas that commonly require insulation include exterior walls, attics, basements, and crawl spaces. Different areas may benefit from specific types of thermal insulation based on their unique needs.

Proper installation is crucial because gaps or compression in insulation can significantly reduce its effectiveness, leading to increased energy costs and decreased comfort.

Essential tools for insulation installation include a utility knife, straightedge, measuring tape, safety goggles, dust mask, and gloves to protect against airborne fibers.

Safety measures include ensuring proper ventilation, using ladders safely, keeping the workspace free from hazards, and keeping family members and pets away from the installation area to prevent accidents.

Proper insulation can reduce heating and cooling costs by up to 20%, leading to significant energy cost savings over time when installed correctly.

Homeowners should assess the type of insulation material, the R-value, specific areas needing insulation, and the installation methods to ensure optimal performance.

Homeowners should plan carefully by gathering necessary tools, prioritizing safety measures, and being aware of their surroundings to create a successful and efficient installation process.

Conclusion

The article "2025 How to Choose and Install Thermal Fiber Insulation for Your Home" serves as a comprehensive guide for homeowners looking to enhance their energy efficiency through proper insulation. It begins by emphasizing the importance of selecting the right type of Thermal Fiber Insulation, taking into account factors such as the R-value and thermal performance of various materials. The piece outlines the different installation methods available, alongside necessary preparations like tools and safety measures that ensure a smooth installation process.

Furthermore, the article provides a step-by-step guide to installing Thermal Fiber Insulation effectively, while also pointing out common mistakes to avoid during the process. Ultimately, it highlights the importance of maintaining and upgrading insulation to maximize efficiency, ensuring that homeowners can make informed decisions that contribute to a more comfortable and energy-efficient living environment.